Whole station search

New Energy Vehicle Wire

EVP High Voltage Shielding Wire for New Energy Vehicles

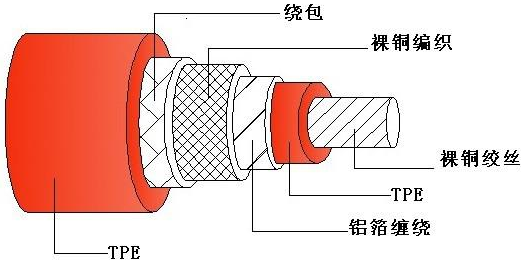

Electric vehicle high voltage wire is mainly used for battery power output, controller connection and motor link.

Wire material

Conductor:annealed soft copper wire

Insulation;125℃/150℃ thermosetting elastomer/ 125℃ environmental protection TPE

Shielding materials:Tinned copper wire、Aluminum Foil Mylar

Sheath:125℃/150℃ thermosetting elastomer/ 125℃ environmental protection TPE

Wire characteristics

Insulation(TPE/Crosslinked polyolefins)

Sheath(Crosslinked polyolefins)

Rated voltage:1500V,High spark voltage 10KV

Bending radius ≥5OD,easy to install

Single flame retardant wire meets VW-1

Insulation material meets UL94-V0

Halogen-free, environmentally friendly wire

Shielding density (≥90%) has good anti-EMI capability.

Reference standard(ISO6722;GB/T25085;GB/T2591;QC/T 1037)

Detailed dimensions are subject to product specifications

Wire material

Conductor:annealed soft copper wire

Insulation;125℃/150℃ thermosetting elastomer/ 125℃ environmental protection TPE

Shielding materials:Tinned copper wire、Aluminum Foil Mylar

Sheath:125℃/150℃ thermosetting elastomer/ 125℃ environmental protection TPE

Wire characteristics

Insulation(TPE/Crosslinked polyolefins)

Sheath(Crosslinked polyolefins)

Rated voltage:1500V,High spark voltage 10KV

Bending radius ≥5OD,easy to install

Single flame retardant wire meets VW-1

Insulation material meets UL94-V0

Halogen-free, environmentally friendly wire

Shielding density (≥90%) has good anti-EMI capability.

Reference standard(ISO6722;GB/T25085;GB/T2591;QC/T 1037)

Detailed dimensions are subject to product specifications

| Conductor | Insulation | Shield&Wrap |

JacketDiameter mm |

Electrical Properties |

|||

|

Wire gauge mm2 |

Conductor Construction NO.xфmm |

Diameter mm |

Outer Diameter mm |

Shield Diametermm | Wrap |

JacketDiameter mm |

Max.Conductor Resistance DC 20℃Ω/km |

| 0.5 | 16/0.20 | 0.90 | 2.9 | Tin-plated Shield | Al-mylar | 5.7 | 37.1 |

| 0.75 | 24/0.20 | 1.10 | 3.1 | Tin-plated Shield | Al-mylar | 5.9 | 24.7 |

| 1.0 | 65/0.15 | 1.30 | 3.7 | Tin-plated Shield | Al-mylar | 6.7 | 18.5 |

| 1.5 | 49/0.20 | 1.60 | 4.0 | Tin-plated Shield | Al-mylar | 7 | 12.7 |

| 2.0 | 64/0.20 | 1.85 | 4.3 | Tin-plated Shield | Al-mylar | 6.25 | 9.42 |

| 2.5 | 79/0.20 | 2.10 | 4.3 | Tin-plated Shield | Al-mylar | 7.0 | 7.6 |

| 3.0 | 98/0.20 | 2.45 | 4.9 | Tin-plated Shield | Al-mylar | 7.85 | 6.15 |

| 4.0 | 133/0.2 | 2.85 | 4.9 | Tin-plated Shield | Al-mylar | 7.5 | 4.71 |

| 6.0 | 190/0.2 | 3.50 | 5.6 | Tin-plated Shield | Al-mylar | 8.2 | 3.14 |

| 10.0 | 323/0.20 | 4.50 | 6.9 | Tin-plated Shield | Al-mylar | 9.9 | 1.82 |

| 16.0 | 513/0.2 | 5.70 | 7.8 | Tin-plated Shield | Al-mylar | 11.1 | 1.16 |

| 25.0 | 879/0.19 | 7.2 | 9.4 | Tin-plated Shield | Al-mylar | 12.6 | 0.74 |

| 35.0 | 1228/0.19 | 8.40 | 11.0 | Tin-plated Shield | Al-mylar | 14.0 | 0.53 |

| 50.0 | 1755/0.19 | 10.0 | 12.6 | Tin-plated Shield | Al-mylar | 16.5 | 0.37 |

| 70.0 | 2479/0.19 | 11.9 | 14.6 | Tin-plated Shield | Al-mylar | 18.3 | 0.26 |